Frequently Asked Question

Multiple Bin Locations

Multiple Bin Locations

There is now the option for setting up alternate bin locations for each item. Before proceeding, make sure that the flag to allow multiple bin locations (field # 45) has been set to [y] in SYSTEM UTILITIES > Systems Setup > Sales Desk > parts billing parameters > Screen 2.

Bin Location Maintenance

This option is used to set up, view a specific location or view all locations for a specified product. Deleting an alternate bin location is also available from this menu. This option is found in the menu inventory > Data Mantenance > Master Files > Bin Location Maintenance.

Bin Location maintenance can also be performed when in the Product Master maintenance by selecting “B(ins)”.

The Bin Type “R”, Retail, is used to identify product in the retail space of the store. Nightly reporting is available to indicate which retail products currently have zero available and need to be replenished from other locations.

The retail bin location can only be the primary location if it is the only location for the product and POS transactions will update the on hand in the Retail location.

Receiving and Stock Transfers will update the quantity on hand in the primary location which is the location shown on screen in Product Maintenance and Inquiry.

Any product with multiple bin locations and the Retail location that has a negative on hand quantity will have the Retail location adjusted up to zero and the primary adjusted down by the same quantity nightly.

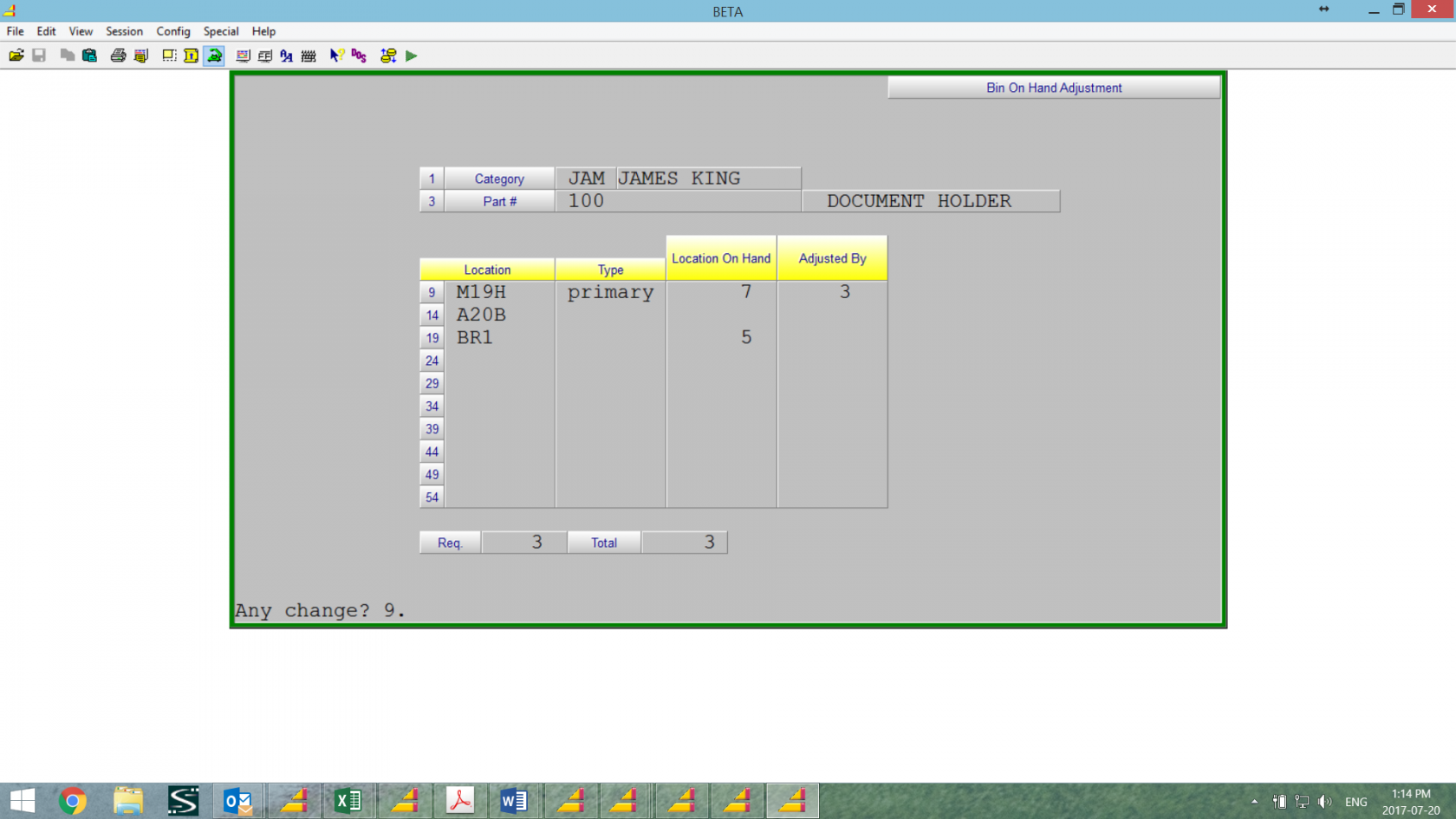

Stock Relocation Adjustment

inventory > Data Mantenance > Inventory Adjustments > Stock Relocation Adjustment

Use this option to adjust the on-hand quantities for each alternate bin location. Enter the category and part number. All of the locations will be displayed. At the any change prompt, press enter to get to the quantity to adjusted by field. Enter the quantity (followed by a minus sign) that is to be moved to other locations. Then distribute that amount to the alternatives. The total field at the bottom must be 0 in order to [f1] accept the entry. Pressing enter after the accept will allow you to continue with further adjustments and “N” will exit to the menu

Stock Relocation Report

This will report all Retail Locations that have and On Hand Quantity of 0 or less which is to be used to replenish these locations. This report will be run automatically each night.

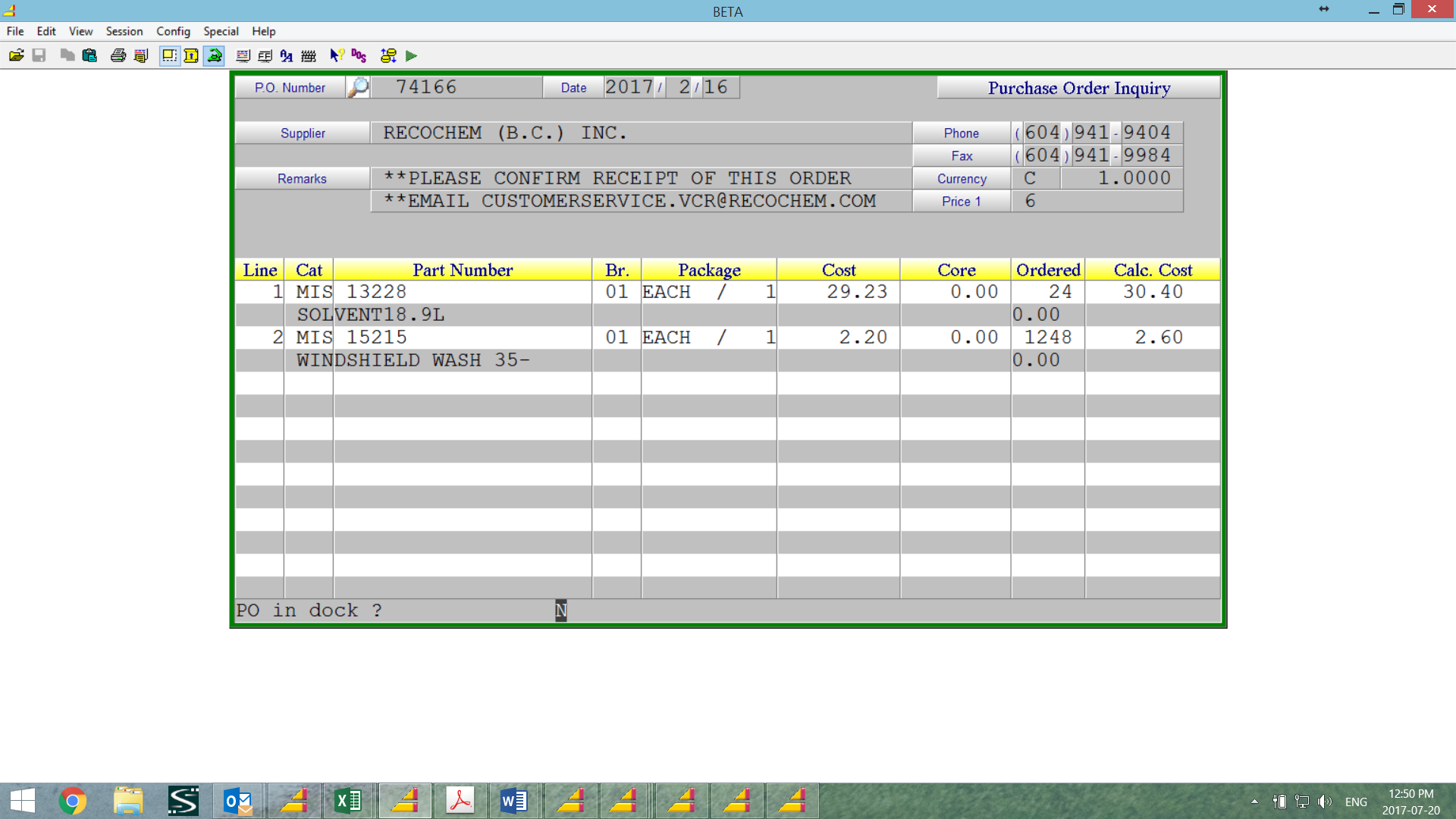

On Dock Purchase Orders

To flag a purchase order as On Dock use Purchasing > Purchase Order Receipts > On Dock Assignment. Enter the PO Number then confirm it is the correct PO, the first page of lines on the PO will be displayed and answer “Y” to create the Dock locations for this PO.

The Dock locations are automatically removed when the PO Receipts Update is completed for the PO.

P.O. Receipts Relocation Listing

Multiple bin location items are automatically received to the primary bin location as listed on the product master maintenance screen. This report provides the information necessary for the user to relocate the quantity received to different locations.

This report is Purchasing > Purchase Order Receipts > P.O. Rec. Relocation Listing

P.O. Receipts Relocation Adjustment

Similar to the Stock relocation adjustment, the user is able to move the recently received quantity from the primary (default) location to multiple locations.

P.O. Receipts Relocation Update

The adjustments made in the above step will be updated.

Alternatively the adjustments can be made using the Stock Relocation Adjustment described earlier in this document.

Inventory Adjustments

When entering Inventory Adjustments, inventory >

Data Mantenance > Inventory Adjustments > Stock Adjustments, if a part is assigned to multiple bin locations you will need to enter the quantities adjusted by bin location when completing the adjustment

The default is to adjust the primary bin but you can change the quantities however the adjusted quantity for the bin locations must equal the total adjustment quantity.

This is the same procedures as used in the Stock Relocation Adjustment

Bin Location Lookup in Invoicing

Products with Multiple Bin Locations that have an on hand quantity will be identified on the invoice screen with a comment of “*MANY*” and products that have zero on hand but are included in an On Dock PO will have a comment of “*DOCK*”.

To check the available quantities for multiple bin locations within the invoicing screen press Shift F4 from the line Type field and you will be prompted for a line number to search. The bin location quantities for the selected part will be displayed in the Information Window. The sale of a product will always reduce the on hand quantity for the Retail bin location if one exists and if no retail location exists the Primary location will be adjusted.

All bin locations will be included on the printed invoice.